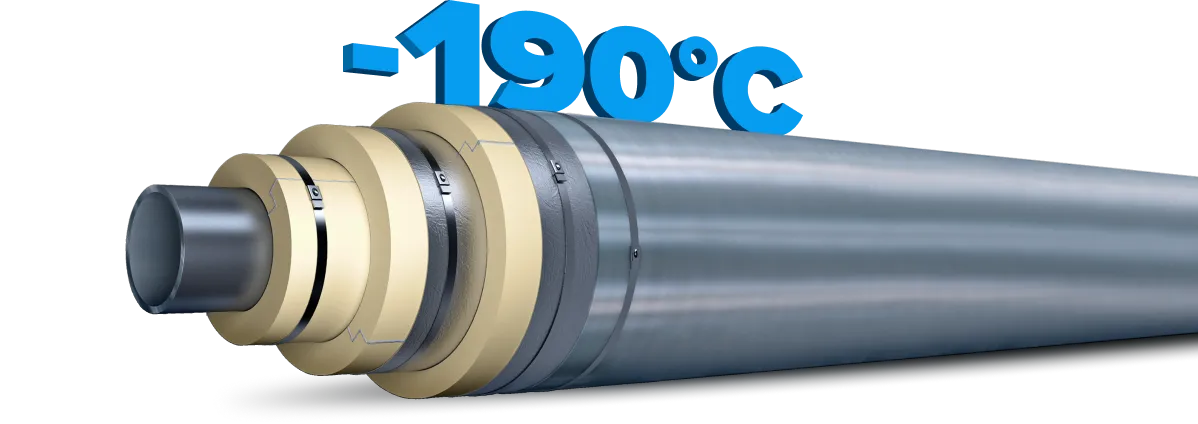

A special line of polyisocyanurate segments and half cylinders designed to insulate pipelines, tanks and vessels operating at extremely low temperatures.Polyisocyanurate (PIR) is a fire resistant cellular polymer obtained by chemical reaction, with an extremely low thermal conductivity coefficient. Each cell of the material is filled with a permanent gas, pentane, whose thermal conductivity is lower than that of air. Due to its structure, the material does not support combustion and does not absorb moisture.

Products are available in the form of blocks (plates), segments, semi-cylinders, one-piece elbows, glued elbows, prefabricated elbows (assembled by the system of tongue and groove through dowels) and elements of other forms, which are made by machining insulation boards and PIR blocks.

The advantages of PIR CRYO compared with alternative types of insulation is as follows:

- Less insulation volume;

- Savings on material;

- Savings on accessories;

- Easy installation;

- Durability;

PIR CRYO products should be stored sorted by grade and size in a dry, closed room at least 1 meter away from heating devices. It is allowed to store PIR CRYO products under a shelter that protects them from atmospheric precipitation and sunlight. It is allowed to store PIR CRYO products outdoors in special packaging that protects them from external atmospheric influences and sunlight for no more than 3 months. The storage area must be equipped with a system of water drainage during rainfall in order to avoid the possibility of soaking (wetting) of the material from below.

Conditional life of the insulation of rigid polyisocyanurate foam is at least 50 years.